Convex Innovative Packaging is redefining what’s possible in the world of packaging, right on our back doorstep.

The Hamilton-headquartered business develops world-first packaging technologies including compostable packaging for dry foods, several slider innovations and a special sealing process now used throughout the world.

They are a passionate provider of high quality, flexible packaging that pushes the boundaries of sustainability, performance and shelf appeal. R&D from a state-of-the-art laboratory is an important part of business at Convex.

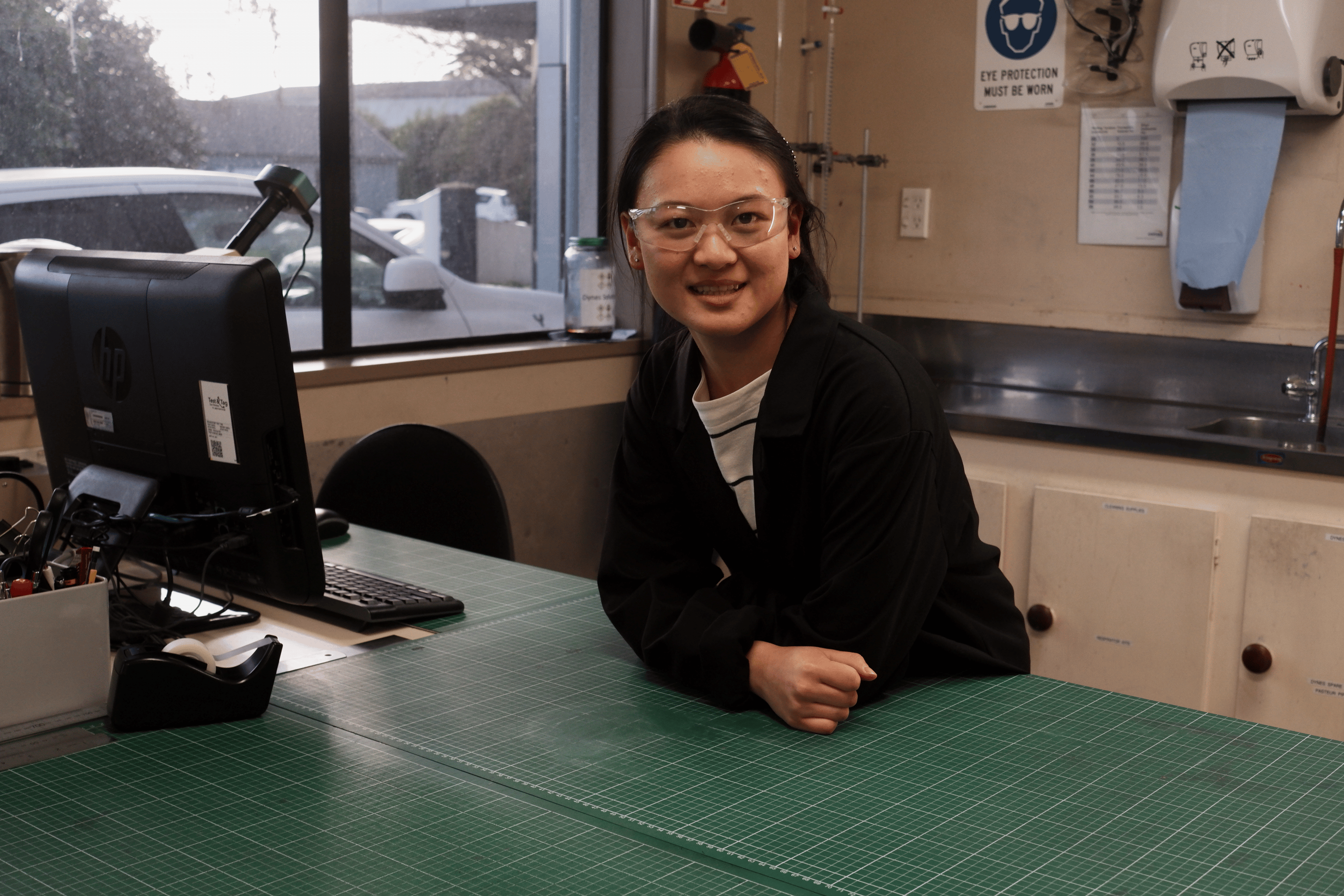

The FutureForce® Team caught up with Convex Laboratory Technician Jennifer Hsi to find out more…

We also sat down with Mechanical Engineering Apprentice Davin Barham to find out more about engineering careers at Convex…

JENNIFER HSI

LABoratory TECHNICIAN

Top Career Tip

“Take any opportunity that comes along that’s good for you and your career.”

– Jennifer Hsi, Laboratory Assistant

A Chat with Jennifer about her role

Jennifer Hsi

Laboratory Technician

Former Hamilton Girls’ High School student University of Waikato Graduate

What is R&D?

Research and development, also known as R&D, is the process used in a business to gather new knowledge to create new products, technologies, services or systems. They will either sell this knowledge or use it within their business.

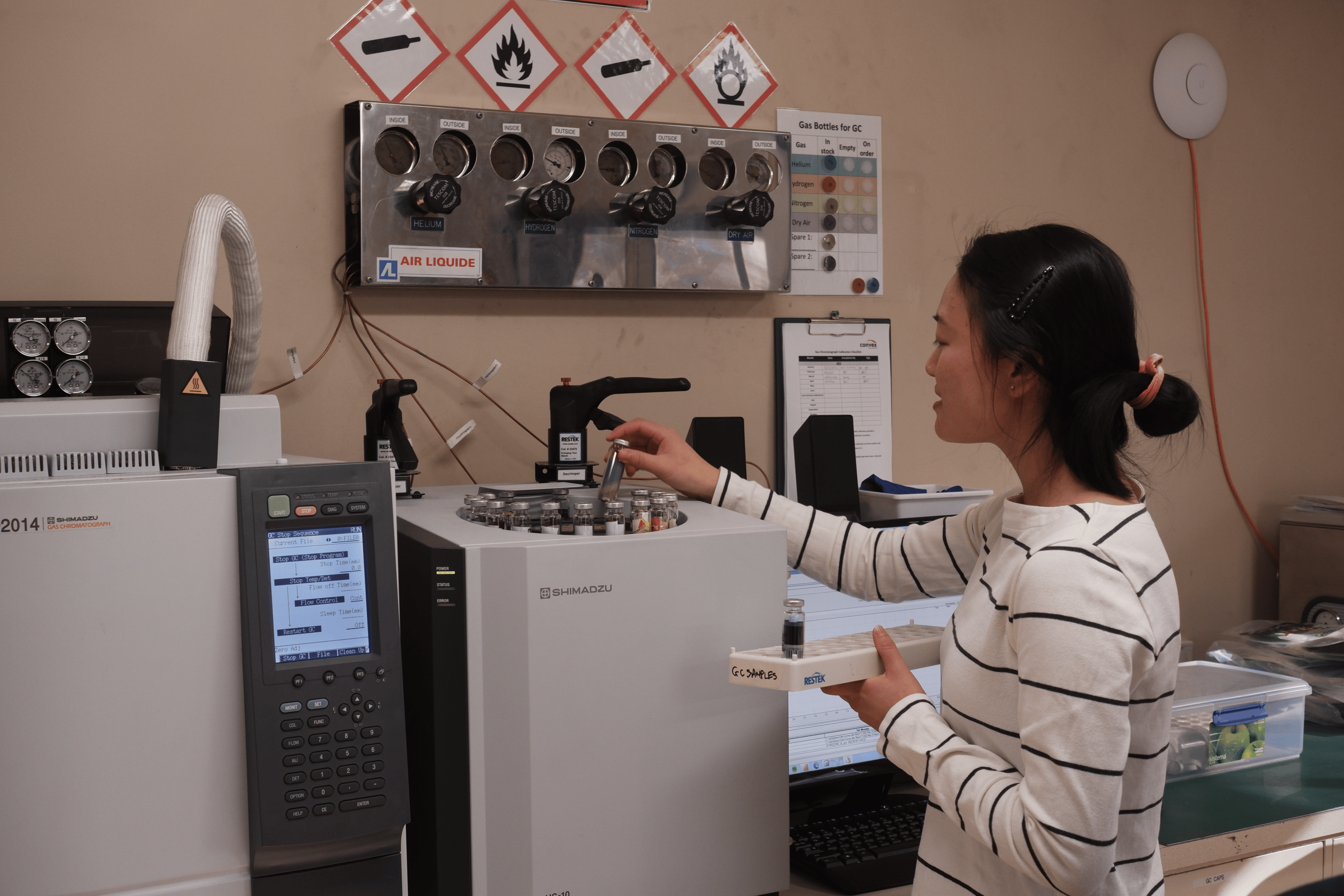

Tell us about your job - what is a laboratory technician?

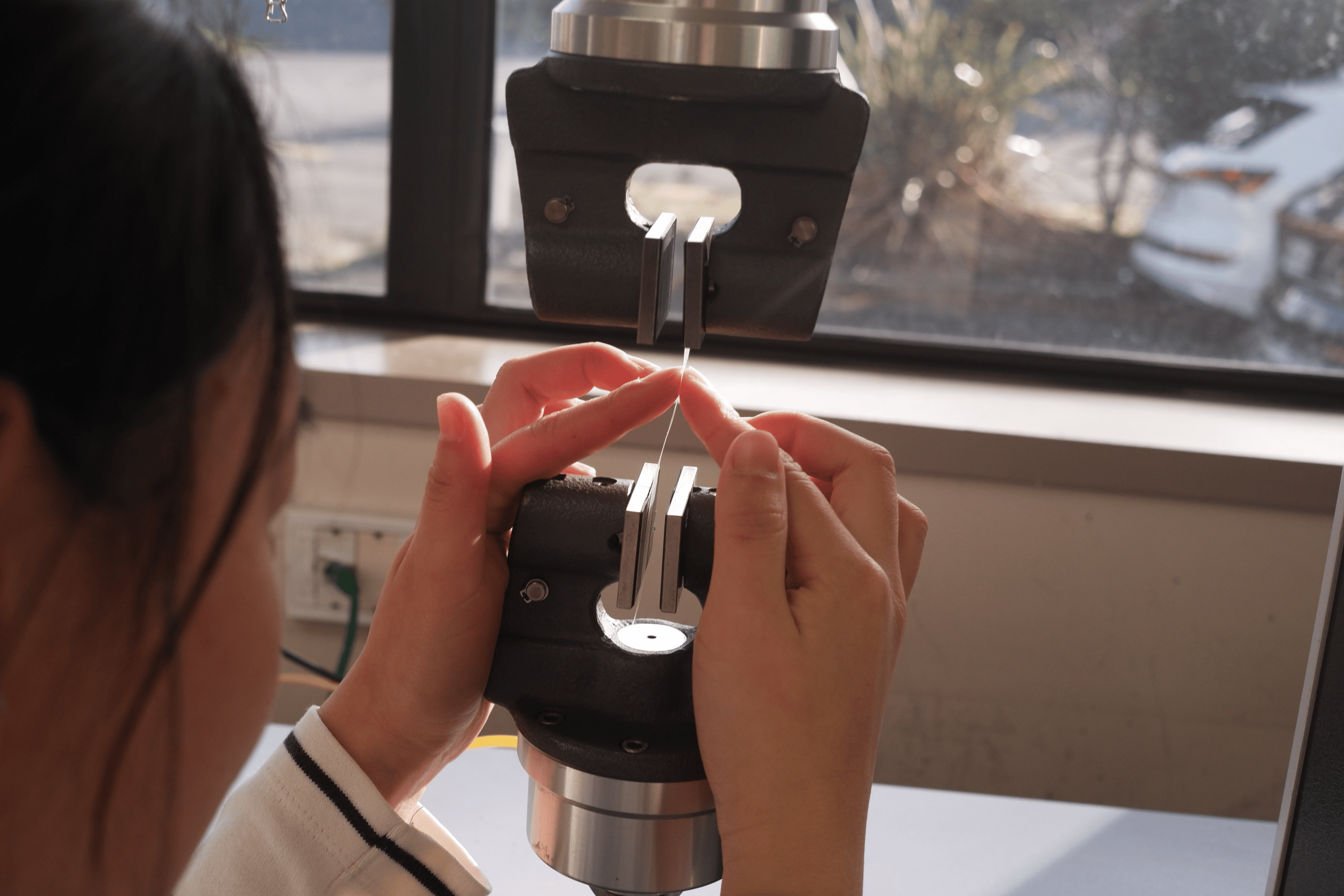

As laboratory technicians we calibrate and operate laboratory equipment. We also provide technical advice for the materials that we make.

How did you get into this role?

I graduated from the University of Waikato with a Bachelor of Science in Chemistry and Earth Sciences.

I was working in a commercial lab before I came here but I was more interested in a technical pathway. When I saw this job was being advertised at Convex, and that included research and development opportunities – I applied and now I’m here!

what does your job involve?

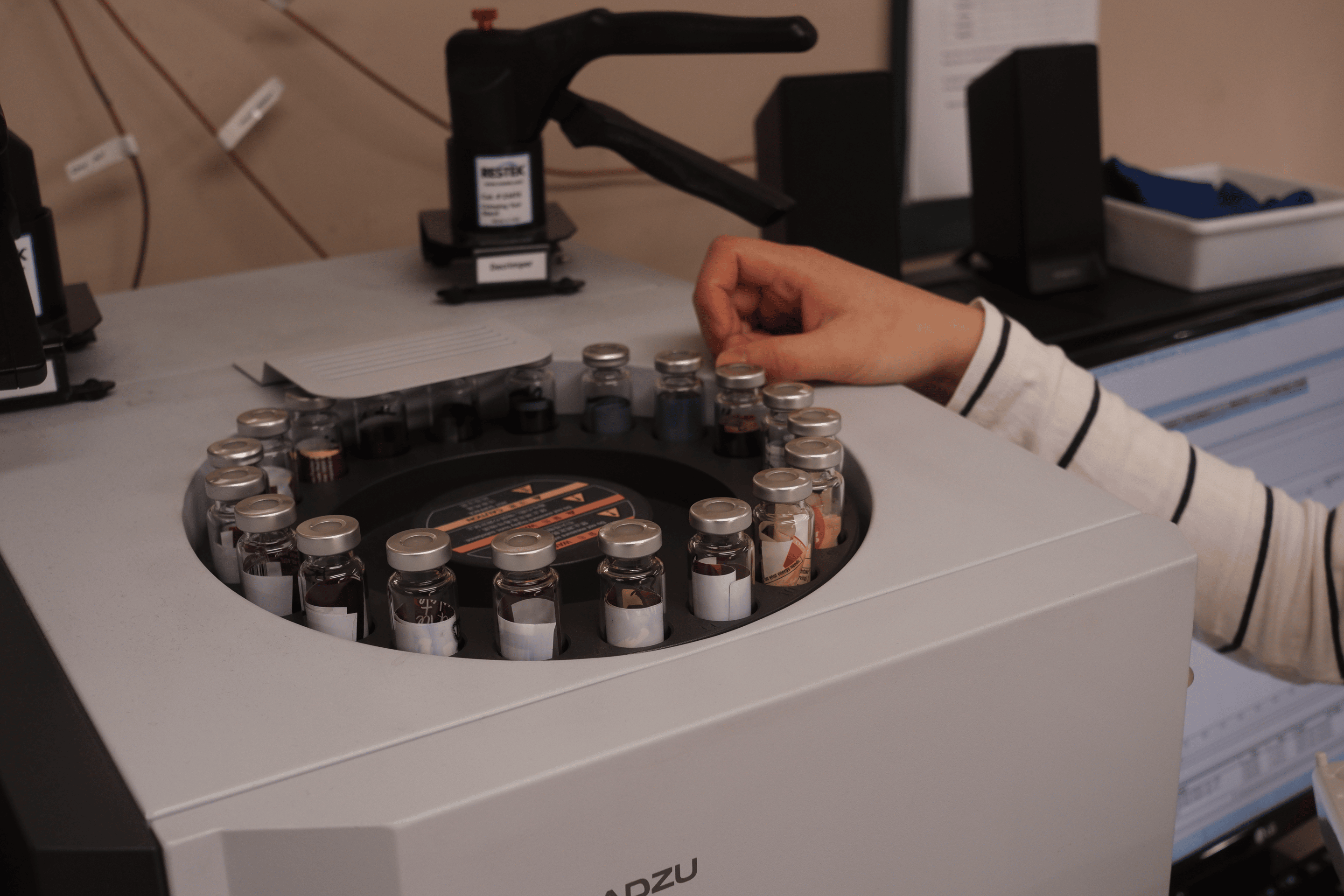

Our job involves using the gas chromatograph for testing retained solvents on the plastics that we manufacture. We print designs on our packaging, so for it to be safe for food packaging, the retained solvents have to be below a specific limit.

We issue a certificate of analysis for some customer products to prove the quality of the product. Our job involves a lot of materials testing, to make sure the physical properties of the plastics are fit for purpose.

We also conduct investigations, which might involve looking at problems that customers might have with their packaging and provide solutions. Other investigations include respiration rate tests for produce, which allows us to design packaging with suitable breathing properties for packing produce. We also do shelf-life investigations to see how long a product lasts in the packaging, and make trial sample bags for customers.

So there’s lots to do!

What school subjects are relevant to your job?

- All of the sciences – particularly chemistry

- Maths

what are some of the challenges you've faced at work?

It was a challenge for me to venture out of my own bubble and interact with the wider company – it’s just not something I’m used to. But I was grateful for the opportunity and a little challenge is always good!

What is your advice for someone starting out at work?

There’s always a lot to learn so make sure you show your interest in learning and take all of the advice you can get.

What are some of the highlights of your job?

The wide variety of things that we do and the opportunites we get to go visit customers. I like doing the shelf life investigations because we trial food products and we get to taste them!

ON THE JOB

One of the things Convex does for customers is carry out laboratory tests to make sure their packaged food tastes just as good in compostable packaging as it does in traditional plastic.

Recently Jennifer had the enviable task of running controlled taste tests for QB’s Crunchy Cheese Snacks, which are packed in these eye-catching packs. The testing confirmed the high barrier EconicClassic packs Convex makes for QB’s keeps their super yummy keto-friendly snacks crisp and full of awesome cheesy flavour

A Chat with Davin about his role

Davin Barham

Level 4 Mechanical Engineering Apprentice

Former Fraser High School student

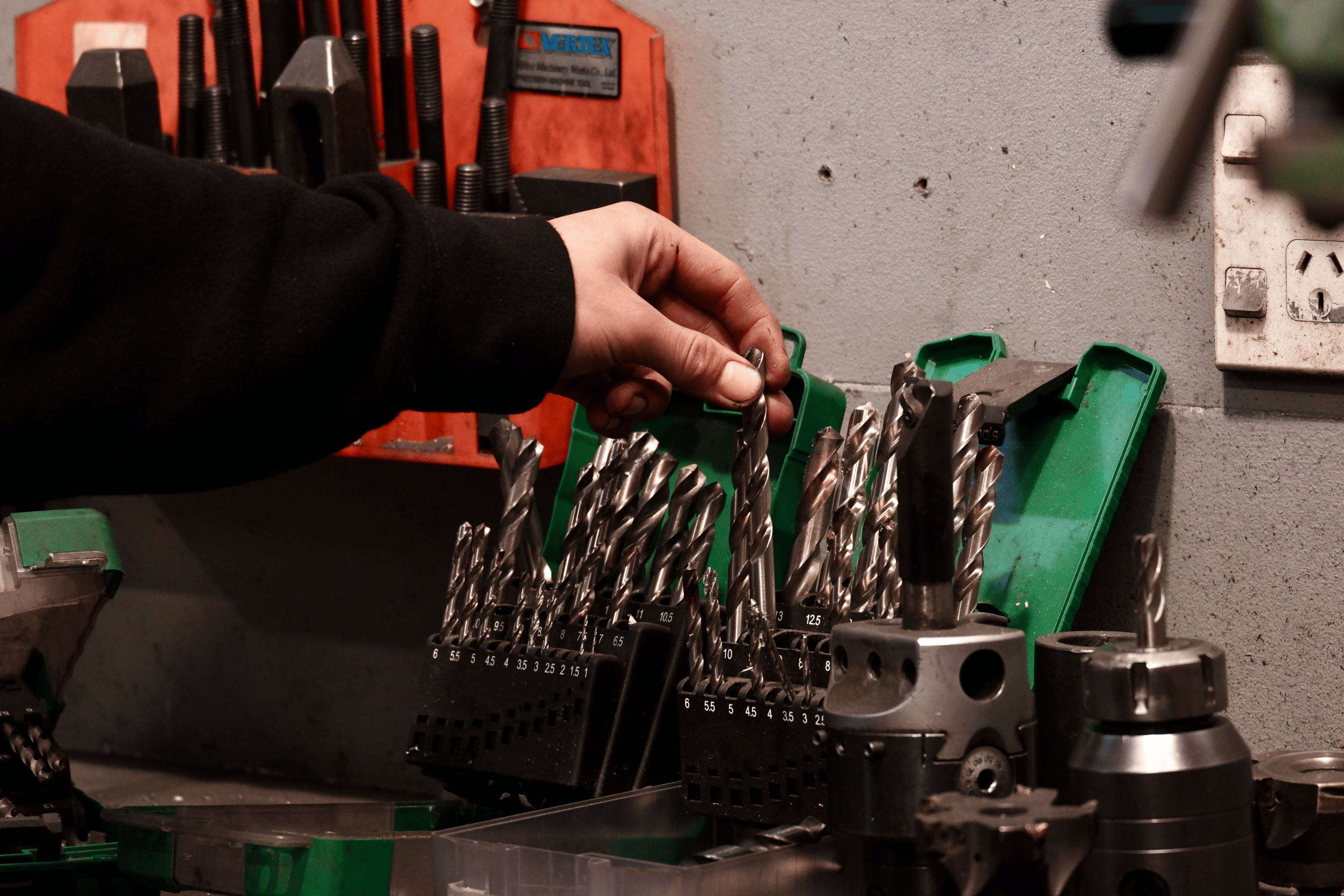

What kind of things do you do at work?

Machining, so milling, the lathe and welding… all the good stuff. It’s great here because you learn a broad range of things, you’re not just a welder or a machinist or just servicing parts; you’re doing it all here. You’re doing pneumatics, hydraulics, machining, fabrication and also building new components.

What are some of the highlights of your job?

My favourite machine is probably the mill.

I like the way the company’s structured… you can talk to anyone about anything. Everyone’s connected and no one is distant or hard to reach. People are happy to have a conversation and help you out.

What were some of the challenges you faced when starting out at work?

There is a bit of a hop between school and being in a workplace. In school, if you don’t weld something properly it’s not the end of the world. But here it’s got to be done properly because it’s got to last. You can’t have a roller up somewhere and have the weld snap and fall off!

What are some of the key differences between school and work?

In school, teachers explain things to a certain degree but here you get a lot more in depth. It’s more precise and technical. It’s good to learn the basics at school but you definitely get a more thorough understanding of what to do and why you’re doing it.

what are some of the school subjects that are relevant to your job?

Definitely metal work or wood work. Being good at maths helps – you don’t have to be a pro but you do have to be all right at it! We’d sit in class and learn Pythagoras theorem and think, ‘I’m never going to use that again in the real world!’ and then you come here and you suddenly need to know the length of the longest side of a triangle – I had to have a bit of a laugh! Things like the circumference of a circle… you might think, ‘I’ll only ever use that once or twice in my twice in my life’ and then you come to work and you’re using it all the time. Makes it way easier and more accurate if the numbers work!

What kind of skills are needed for this job?

A bit of an eye for detail, things need to be done properly. Someone who’s willing to work hard. If something’s broken or urgent then you work until the work’s finished – lunch waits until you’re done! You’ve got to be accurate with your work. I think the biggest thing is just listening and applying what you learn. It’s alright to make a mistake but if you’ve been told exactly not to something, then don’t do it!

“It’s great here because you learn a broad range of things, you’re not just a welder or a machinist or just servicing parts; you’re doing it all here.”

– Davin Barham, Mechanical Engineering Apprentice

MORE ABOUT CONVEX…

Convex has been in the business of innovative packaging for more than 40 years.

Their full-equipped plant features the latest extrusion, conversion, pre-press, lamination and printing technology, along with market-leading warehousing and distribution and R&D lab.

Along with offering a wide range of top quality flexible films, ready made bags, promotional materials and labels, they offer customers:

– Product development

– Technical support

– Award-winning printing

– Customised packaging solutions

“Be it a world-first process for converting heavy duty sacks, a revolutionary carry bag handle, or a high barrier compostable coffee bag – we thrive on challenges and will do everything we can to develop a workable solution that meets customer specifications and price point.”

Find out more about how Convex leads the way in sustainable packaging

> convex.co.nz