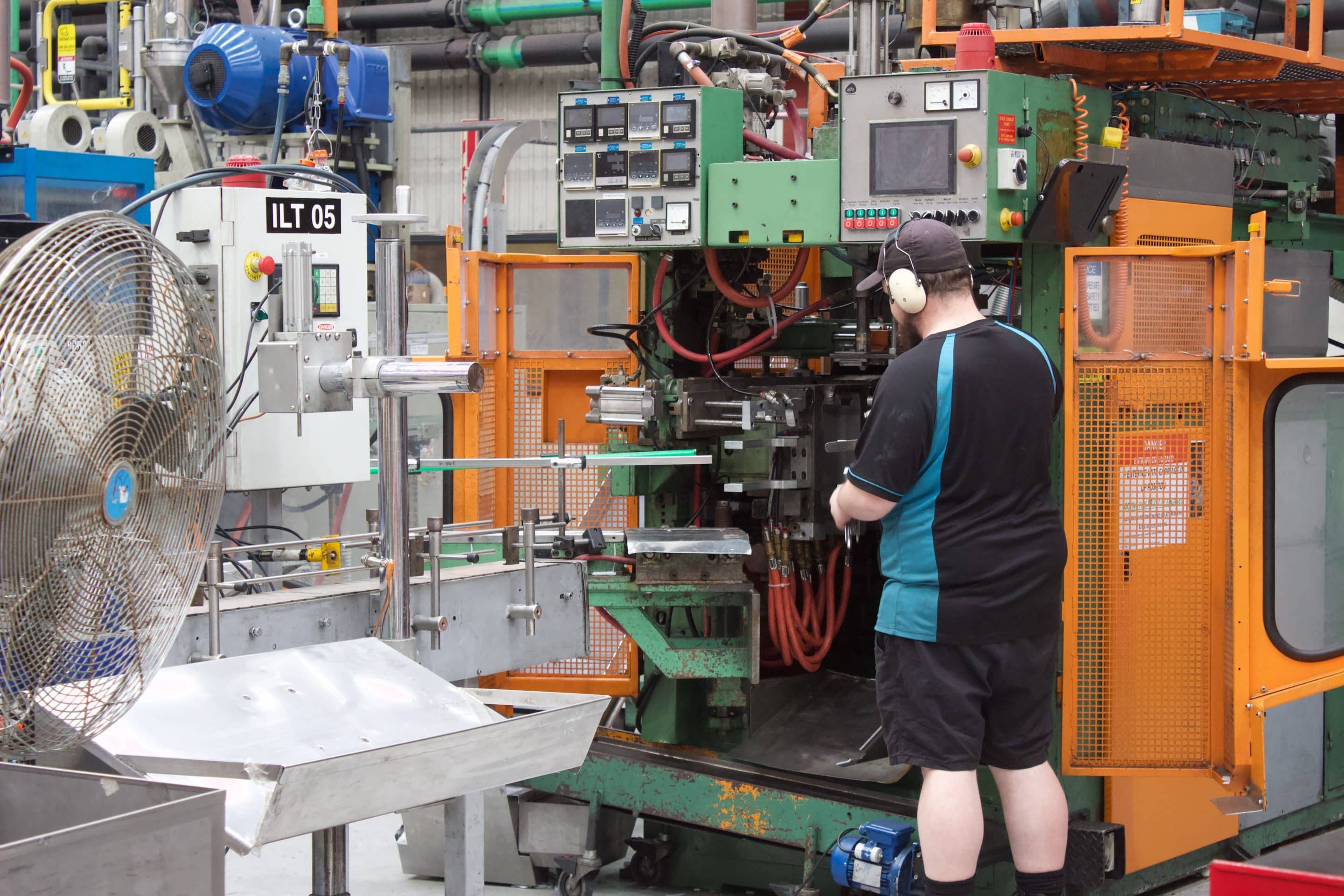

A Die Setter, like Ben from PACT Packaging, is the person who keeps the machines running smoothly, ensuring everything is set up and ready to produce the products we use every day. Through the use of special tools across the production line, the plastics are shaped and cut to fabricate a finished product.

It’s a hands-on role that’s key to the success of the plastics manufacturing process, and it’s perfect for someone who loves working with their hands, keeping things running efficiently, and enjoys a solid day’s work!

Check out what Ben has to say about it…

Ben Wallace

Die Setter/Fitter

Key Terms to know

Tool – The term ‘tool’ broadly refers to any piece of equipment that assists in the manufacturing process. The term ‘tool’ can also be used to describe a die or mould.

Die – This is the specialised mould that shapes the molten plastic into a specific product as it is extruded from the machine.

MORE ABOUT BEN’S ROLE AS A DIE SETTER

BEN WALLACE

Former Fraser High School Student

What is a Die Setter/Fitter?

How did you get into this work?

What is blow moulding?

We extrude a tube of plastic and close a tool around it, then blow it into shape. As it comes out you have all the excess plastic which you punch off and then we will leak test it to ensure durability.

What does your work day look like?

What sort of person do you have to be?

You need an interest in mechanical work, should like to be hands-on, able to lift heavy and not afraid to get dirty. Our workshop can also get quite hot because of the heat of the plastic, which takes getting used to.

What have you learnt on the job?

What are the highlights in your line of work?

What qualifications have you got, and what might be your next step?

If a technician spot opened up I would love to step up to that. Technicians are in charge of certain machines and make sure they are working well, and they also oversee the process.

Ben’s Career Advice

What challenges have you found?

What do you wish someone told you when you left school?

What advice would you give someone looking at work in this industry?

What is the best career you ever received?

About PACT Group

pactgroup.com/nz/

GRAB A SNAPSHOT OF BEN’S CAREER PROFILE