Skilled welders vital for structural engineering

Structural engineering has been used for thousands of years for building ancient and modern structures, including the pyramids in Egypt and the Acropolis in Greece.

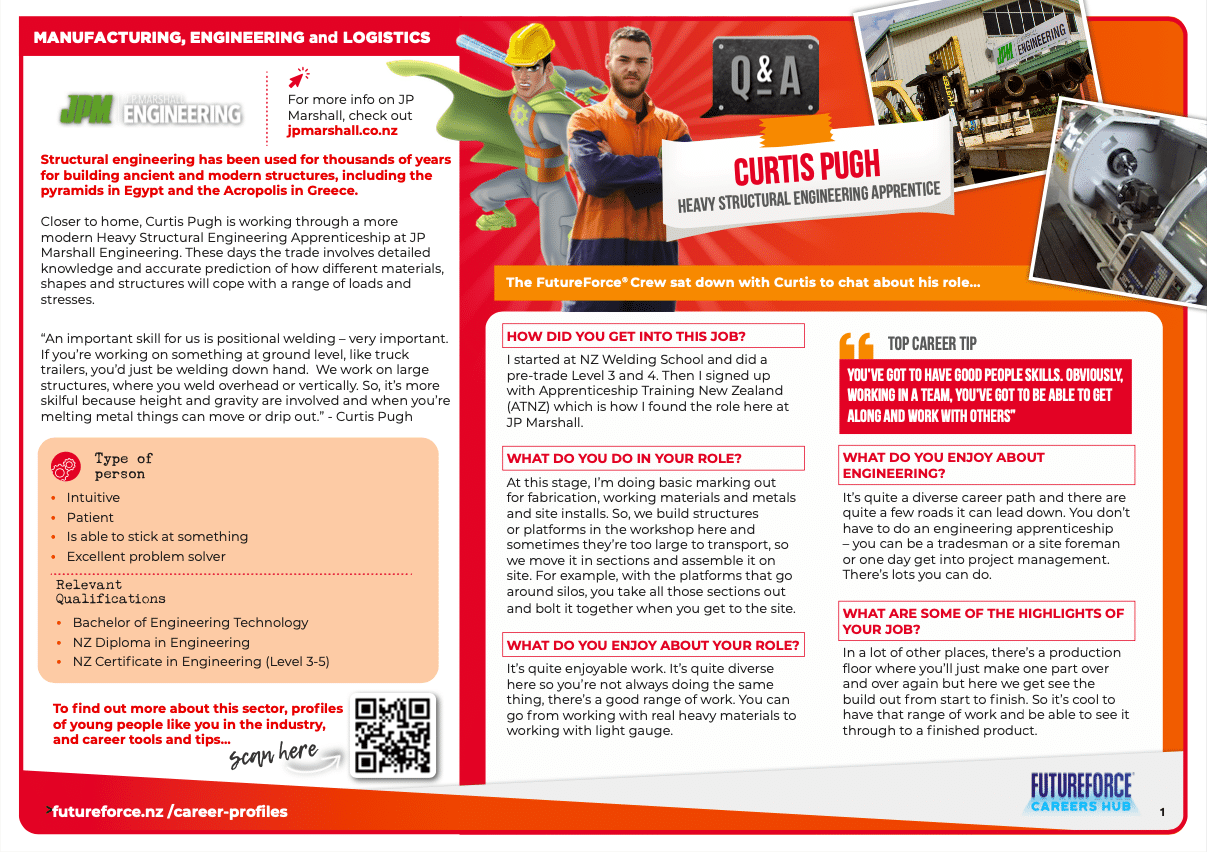

Closer to home, former Hamilton Boys’ High student Curtis Pugh is working through a more modern Heavy Structural Engineering Apprenticeship at JP Marshall Engineering. These days the trade involves detailed knowledge and accurate prediction of how different materials, shapes and structures will cope with a range of loads and stresses.

“An important skill for us is positional welding – very important. If you’re working on something at ground level, like truck trailers, you’d just be welding down hand. We work on large structures, where you weld overhead or vertically. So, it’s more skilful because height and gravity are involved and when you’re melting metal things can move or drip out.”

FutureForce® decided to find out more about this exciting career with huge local and global scope…

Curtis Pugh

Heavy Structural Engineering Apprentice

“You’ve got to have good people skills. Obviously, working in a team, you’ve got to be able to get along and work with others.”

A Chat with Curtis about his role

Curtis Pugh

Former Hamilton Boys’ High

School Student

How did you get into this job?

I started at NZ Welding School and did a pre-trade Level 3 and 4. Then I signed up with Apprenticeship Training New Zealand (ATNZ) which is how I found the role here at JP Marshall.

What do you do in your role?

At this stage, I’m doing basic marking out for fabrication, working materials and metals and site installs. So, we build structures or platforms in the workshop here and sometimes they’re too large to transport, so we move it in sections and assemble it on site. For example, with the platforms that go around silos, you take all those sections out and bolt it together when you get to the site.

What do you enjoy about your role?

It’s quite diverse here so you’re not always doing the same thing, there’s a good range of work. You can go from working with real heavy materials to working with light gauge.

You don’t have to do an engineering apprenticeship – you can be a tradesman or a site foreman or one day get into project management. There’s lots you can do.

What are some of the challenges you’ve found starting out in your career?

Sometimes you find yourself in challenging situations where you either make it or break it. So that’s where that willingness to learn comes in. You just need to get stuck in and get onto it. When you’re in your apprenticeship, that’s your time to focus on what your more experienced teammates are doing. Obviously they’ve been there and done that so there’s a lot you can learn from them.

What are some of the highlights of your job?

In a lot of other places, there’s a production floor where you’ll just make one part over and over again but here we get see the build out from start to finish. So it’s cool to have that range of work and be able to see it through to a finished product.

What advice do you have for keeping balanced and managing stress?

I like to do Thai Boxing, sports and stuff, it helps to have another focus outside of work.

What’s your advice for young people starting out in their careers?

It’s a hard one to answer without seeming too obnoxious about it but some young people can be big-headed, and they come in and think they know it all. So you’ve just got to be a bit humble and respect the process. You’re not going to be the boss on day one, it takes time but you’ll get there in the end.

A lot of people want to get into a trade with no prior experience which can be hard with engineering. So doing something like a pre-trade or going to welding school is good to help you pick up the basics before being put in that environment.

Did you know?

JP Marshall Engineering in Hamilton has been a great place to work for over 60 years. The company is one of New Zealand’s largest and most experienced steel fabricators and commercial and industrial engineering providers.

JPM offers services including:

- Design

- Laser cutting

- CNC pressing

- CNC machining

- Welding

- Project management

- Installation

- Site services

So, a great variety of work for bright young people keen to kick start their engineering careers!

Find out more at

jpmarshall.co.nz

skills & education

What are some of the skills you might need to have in this kind of role?

You’ve got to have good people skills. Obviously, working in a team, you’ve got to be able to get along and work with others. Time-management is important too to make sure you can get through everything and know what you need to do.

You need good maths skills. A background in fabrication is helpful. And welding – obviously!

Of course, you don’t have to start with all those skills on day one but having a willingness to learn is a big thing – there’s a lot of on-the-job training.

What school subjects are relevant to your job?

Maths is an important one because you need to be able to know the different formulas and equations. It’s definitely helpful.

You could take engineering or metal tech, that would make sense! Or even woodwork. All of them are a good introduction to handling and working with machines and different materials.