Did you know that Sealed Air – the company behind BUBBLE WRAP® – is committed to offering excellent engineering career opportunities to young people right here in Waikato?

A global company with a branch in Hamilton, Sealed Air recently launched a Technical Cadetship Programme where four young engineers will spend three years working across various departments of the business including:

- Product Development

- Engineering

- Project Engineering

- Manufacturing

- Quality

- Maintenance

Whether it’s protecting goods, preserving food, or providing healthcare solutions, Sealed Air’s products and services – along with their commitment to sustainability and upskilling their sector – have made them a leader in protecting everything that’s important to people with a range of packaging solutions.

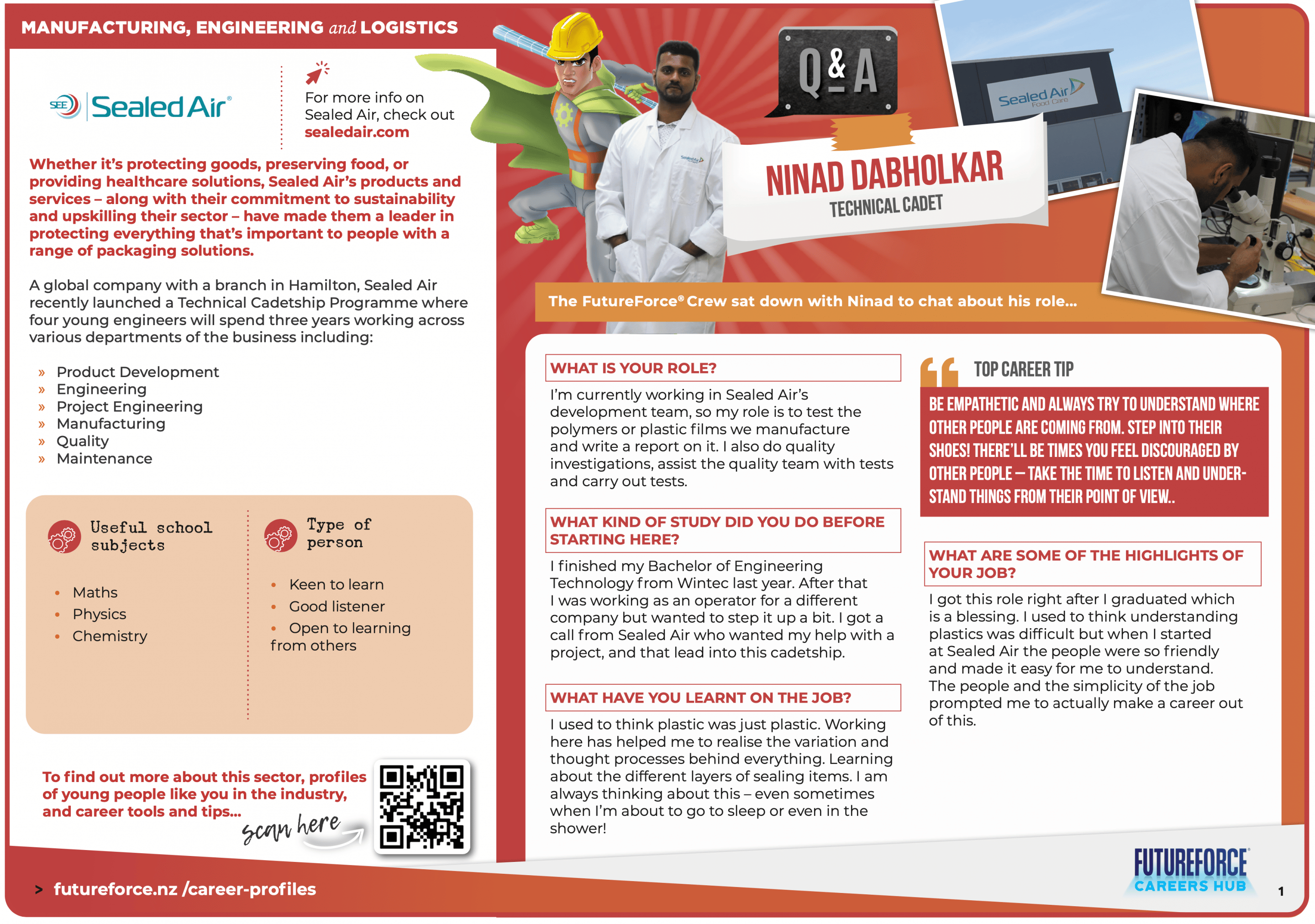

The FutureForce® Team caught up with Sealed Air Technical Cadet Ninad Dabholkar to find out more…

Ninad Dabholkar

TECHNICAL CADEt

Top Career Tip

“Be empathetic and always try to understand where other people are coming from. Step into their shoes! There’ll be times you feel discouraged by other people – take the time to listen and understand things from their point of view.”

A Chat with Ninad about his role

What is your role?

I’m currently working in Sealed Air’s development team, so my role is to test the polymers or plastic films we manufacture and write a report on it. I also do quality investigations, assist the quality team with tests and carry out tests.

What kind of study did you do before starting here?

I finished my Bachelor of Engineering Technology from Wintec last year. After that I was working as an operator for a different company but wanted to step it up a bit. I got a call from Sealed Air who wanted my help with a project, and that lead into this cadetship.

What do you do at work?

My role will change throughout the cadetship. Lately I have been working to support the laboratory. I receive test requests, conduct physical tests in the lab, and follow this with chemical separation analysis if needed depending on the different melting temperature of the polymer. We are testing the physical and chemical properties of the film. We are looking for things like the mechanical strength, how smooth the film is, if there are any impurities, and we also measure the oxygen and moisture transfer capability.

Then we take this analysis and use it for different applications (or packaging different items). For example, let’s say you want to package chicken – chicken would use a film with a high oxygen barrier in order to keep your food fresh.

What have you learnt on the job?

I used to think plastic was just plastic. Working here has helped me to realise the variation and thought processes behind everything. Learning about the different layers of sealing items. I am always thinking about this – even sometimes when I’m about to go to sleep or even in the shower!

What got you interested in this type of work?

I love formula one racing. Because of that, I always wanted to learn about cars. Once I got into that I wanted to dig deeper into automobiles and so I thought engineering would be a good path to go down and pursued my course of study.

What are some of the highlights of your job?

I got this role right after I graduated which is a blessing. I used to think understanding plastics was difficult but when I started at Sealed Air the people were so friendly and made it easy for me to understand. The people and the simplicity of the job prompted me to actually make a career out of this.

What do you enjoy about working at Sealed Air?

Every day brings something new. Things happen around the workplace that make me think – wow, I never thought about that! Imagine eating the same food over and over again – you get sick of it. The work we do is always evolving and I don’t always expect what a new day will bring.

we asked NINAD a few more questions about working at SEALED AIR…

What do you enjoy about working at Sealed Air?

Every day brings something new. Things happen around the workplace that make me think – wow, I never thought about that! Imagine eating the same food over and over again – you get sick of it. The work we do is always evolving and I don’t always expect what a new day will bring.

What qualities make a good candidate for your work?

Someone who’s extremely keen to learn what’s already there, what’s out there, and what’s coming (past, present, future). Technology is changing so quickly. Having a learning attitude is one of the most important qualities.

You need to be a good listener. There’s wisdom in what’s already there in a company so you need to be open to learning everyone’s opinions. Take what’s out there and keep developing from there!

CruNching the Numbers with Sealed Air

» 16,500 team members

» 114 countries/territories

» $US 5.5 billion revenue

» 98 manufacturing facilities

» 39 packaging design and application centres

» 2875 product patents

Useful School Subjects

- Mathematics

- Physics

- Chemistry