Light Fabrication at Stafford Engineering

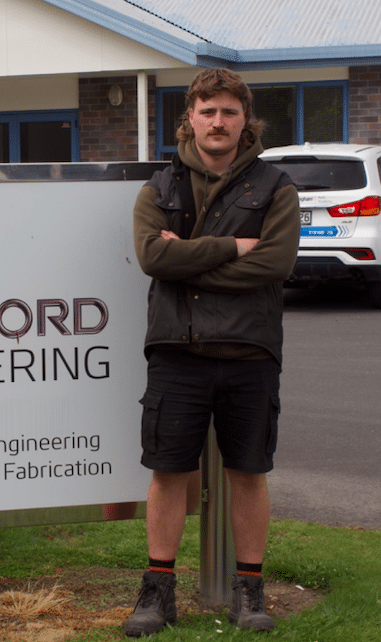

Former Te Awamutu College student Jack Ruthe has turned his hobby into a hands-on career at Stafford Engineering.

Starting with holiday work experience, Jack discovered his love for working on cars, metalwork and welding meant he was well suited for a Light Fabrication Apprenticeship at the Hamilton business.

Doing trades academy at school gave him a great stepping stone, helping him get a feel for fabrication work before diving into it full-time.

Now he’s learning the craft of fabrication, from welding and polishing to creating everything from custom parts to large-scale equipment—all while honing his skills and gaining new independence as an apprentice.

Jack’s story is proof that following your interests and seizing opportunities can lead to a fulfilling career pathway…

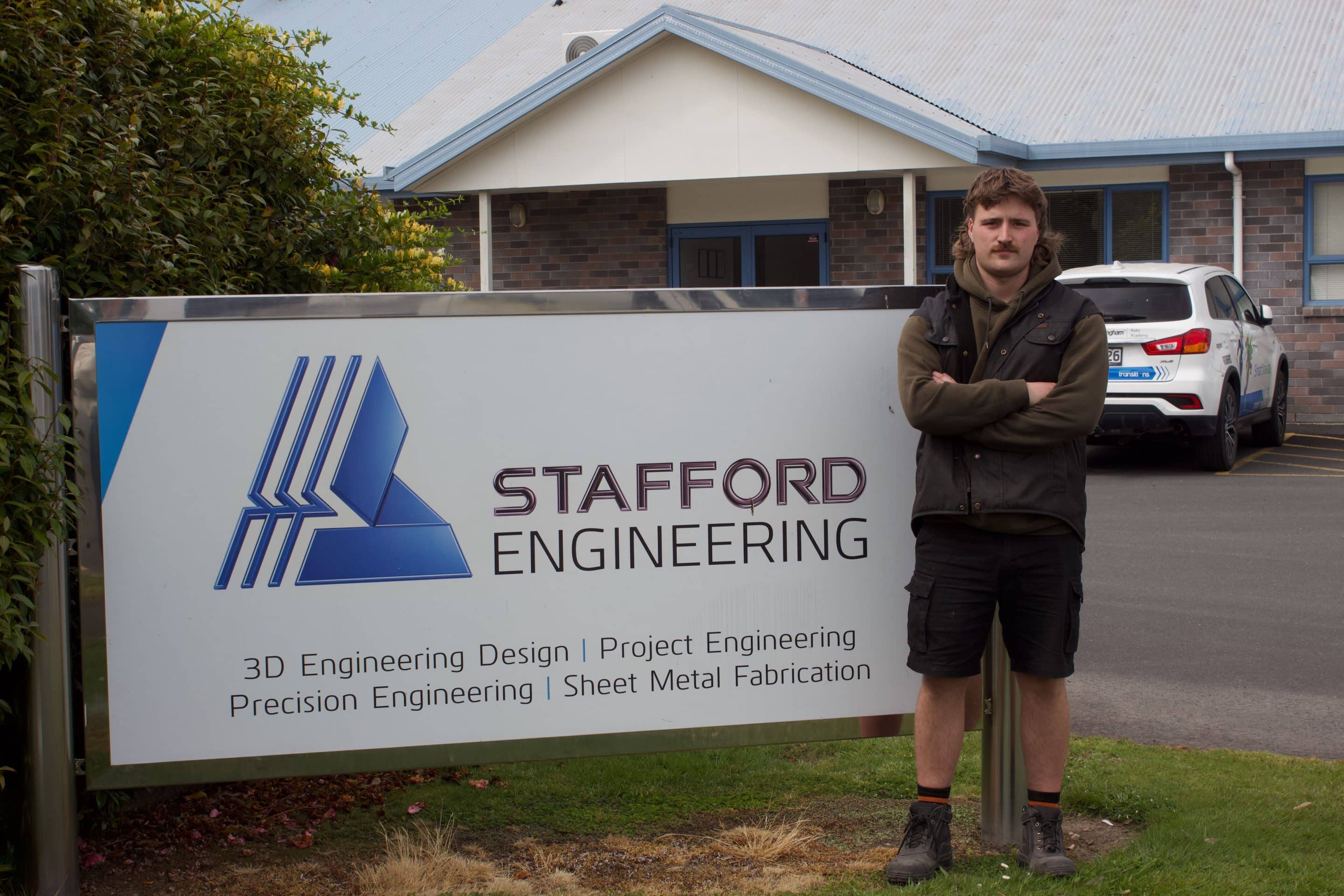

Jack Ruthe

Light Fabrication Apprentice

Jack’s Career Advice

“Don’t be afraid to ask questions! It’s better to ask a question than to make a mistake. But if you do mess up, make sure you acknowledge it – it’s easier to fix things earlier in the process.”

A Chat with Jack about his role

Jack Ruthe

Light Fabrication Apprentice

Former Te Awamutu College student

How did you get started at Stafford Engineering?

I was in school looking to pursue my career in metal fabricating, which I had always had a passion for. My dad found me a place at his mate’s workshop, here at Stafford, to do work experience in the school holidays. This helped me know what to expect and solidified what I wanted to do. From there I got into an apprenticeship. It was a big help that my dad had those personal connections to get me started!

What got you interested in this career?

My hobby is working on cars. I sort of based my career on this passion and knew I wanted to do something involving welding. I did Trades academy at school, which I really recommend to others. Get a feel for what is out there and gain some experience before deciding where you will go.

What do you do as a light fabricator?

We fabricate all types of products or components out of metal, from sheets and tubes to big blenders. Welding and polishing are two tasks that I have done while being here. Doing polishing helped as it gave me a different view of the process, so I now know to polish before I do my welds to make things easier later.

What do you love about your job?

I like the variety of jobs, and the opportunities and independence I have been given here. Another apprentice and I were just given an opportunity to make a blender on our own. I have also done a stay away job in Christchurch, learning from qualified people, which was a great learning experience.

What other study have you done?

I am currently working to complete my apprenticeship, but in school I did one day a week of trades academy and one day a week of pre trade, alongside summer work experience here at Stafford.

What have you learnt on the job?

Over time I have learnt the basics of the trade; welding, polishing and reading drawings. I have also improved my ability to communicate with colleagues and learning how to report to a manager. There is a certain way that you speak to a manager compared to speaking to your colleagues, so finding a balance of professionalism and banter is key.

What do you like most about working at Stafford?

I like how at Stafford they look after their employees well. They make a good effort to give us a variety of work and share around the different tasks. No one gets stuck on any one job, and we share the work around the team.

What are some challenges you have had?

When I first started it was getting a good sleep schedule in and adjusting to early mornings. I have also had to learn how to maintain a good relationship with my coworkers. Not getting mad at people’s mistakes or taking things they say to me to heart.

Jack’s advice for starting out

What school subjects are important for fabrication?

I have found maths, metal technology and graphic design to be most important. Graphic design is something I have used more than I thought I would. I do a lot of drawings in my apprenticeship. You are given a plan for a job and must interpret the drawing.

What sort of person is suitable for work in fabrication?

Someone that is focused and organised, has an eye for detail, and takes pride in their work. That is what makes Stafford stand out – our attention to detail and quality of our work. Sometimes the job may take a bit longer to be done right, but the customers prefer this.

What advice would you give to someone deciding on career?

Just get out there and do what you want to do, not what others expect of you. I found it hard listening to what people around me said I should do and then thinking about what I want to do. There is more to a career than making money, and work is going to be more enjoyable if you do like what you are doing. Often this leads to career progression and higher pay.

What advice would you give for an apprenticeship in fabrication?

Work experience is a great starting point, to get a feel for the job and see if it is right for you. You just have to try things and if you don’t like it, you try something else.

What advice do you have for managing stress and keeping balance?

Making time for your hobbies outside of work and building a healthy relationship with your co-workers. I found this has helped because a lot of them will have been through similar things, so you can have a chat and hear their experiences.

About Stafford Engineering

Stafford Engineering is a successful Hamilton business with a proud history of developing world-class engineers for the future.

Established in 1986, Stafford is a multi-disciplined precision engineering company servicing clients involved in the local and global food processing, packaging and pharmaceutical industries.

Stafford started life as a machine shop and has grown to include world-class design and fabrication capability, with about 60 team members committed to keeping customers happy and business humming.

Learn more about Stafford

@stafford.co.nz

Read more from Stafford Engineering